From supplier to partner

Dow Chemical Company enhances the quality of their pH measurements and cut costs

An opportunity for partnership

Endress+Hauser, having the know-how in the field, recognized this as an opportunity to partner with Dow. “We approached Dow looking for ways to cut costs,” says Todd Lucey, Managing Director, Endress+Hauser USA.“We quickly found that there was huge potential for improvement of the pH measurements.” High maintenance expenses and low reliability and availability marked the situation on-site. “We offered to handle the pH measurements on our own – with the measurement, in a way, becoming a service.”

In 2009, the economic crunch impacted U.S. manufacturing in many areas, including employment. Also, Dow had to cut back and further stretch their resources. “With the shortage of analyzer experts putting a burden on our workforce, we needed help finding the right people resources,” explains Paul Coram, who is responsible for Process Analyzer Reliability at Dow.

New, cutting-edge technology on a common platform

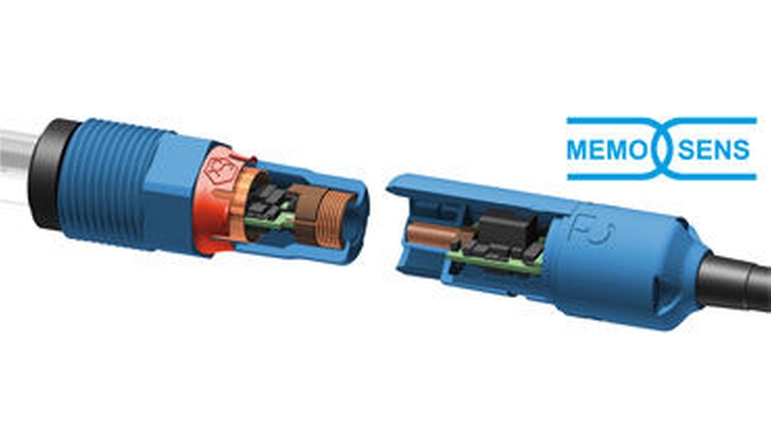

The chlor-alkali process was the first to be tackled. The pH value is considered crucial in the proper control of the electrolysis - and the analog measuring points caused a lot of trouble. The high-resistance signals are susceptible to faults and malfunctions. This caused the maintenance team to put in many nonscheduled hours. First, Endress+Hauser fit all measuring loops with digital Memosens technology giving Dow the opportunity to upgrade to new technology on a common platform.

Preventative maintenance

Memosens probes rely on magnetic induction, both for signal transmission and power supply. This tackles the major problems in pH measurement at their roots. Memosens probes can be pre-calibrated in the lab to be exchanged quickly on-site and only when necessary. Gary Cowart Jr., Process Analyzer Leader at Dow's Houston hub operations sees key benefits in the concept of preventative maintenance. “We could even increase our safety efforts by reducing the time personnel are spending in the field.”

A continuous improvement process

The options and opportunities offered by the collaboration are far from exhausted. “We've triggered a continuous improvement process,” says Tracy Doane-Weideman. In due course, all measuring points will gradually be retrofitted with wireless signal transmission using WirelessHART technology. “We want to get to the point where we centrally analyze all the sensor status information to improve maintenance management even further.”

Read more about similar topics:

Downloads

-

From supplier to partner.pdf

File size:

1.6 MB

File name:

WP01014C24_EN_01.15.pdf