Improving the efficiency of natural gas sweetening units

Improvement efforts start with accurate measurements to ensure effective monitoring and control

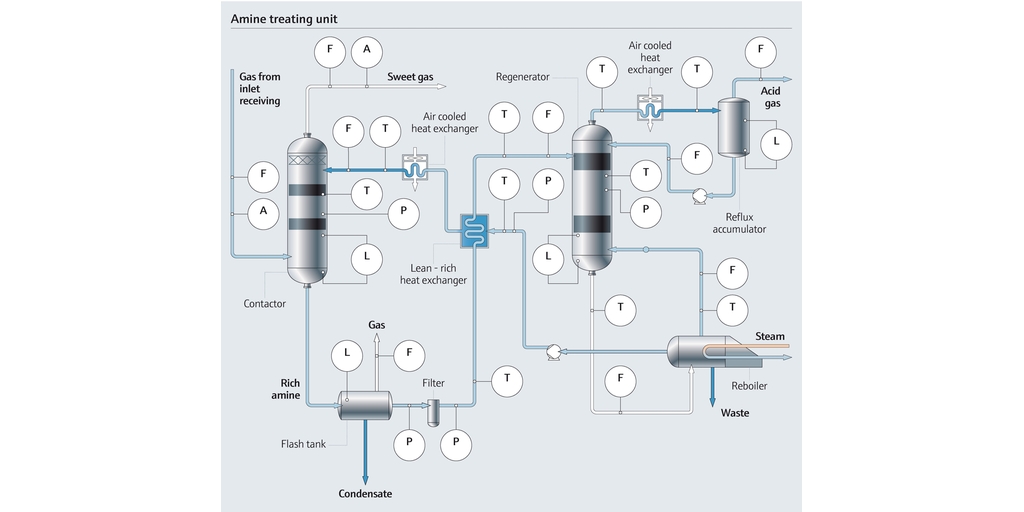

After natural gas is extracted from onshore and offshore sites, it needs to be transported and processed. Raw natural gas is processed for purification, separation and liquefaction. Like most processes, amine sweetening units require proper measurement to operate safely and efficiently with minimal required maintenance. Selecting the best instrument or analyzer for each measurement point can be quite challenging as many recent advances have resulted in alternatives to traditional solutions.

Amine treating

Operating procedures for developing sour gas fields must be rigorous and well designed to ensure personnel safety. Key measures of efficiency are the quality of the gas processed, and the energy used versus the level of treatment performed. Different gas sweetening processes are used depending on the quantity and quality of acid gas contaminants to be removed. Read about the different processes used and how amine treating can be cost saving!