Basics of continuous level measurement

A look at ultrasonic, free space radar, guided wave radar, capacitance, gamma and pressure

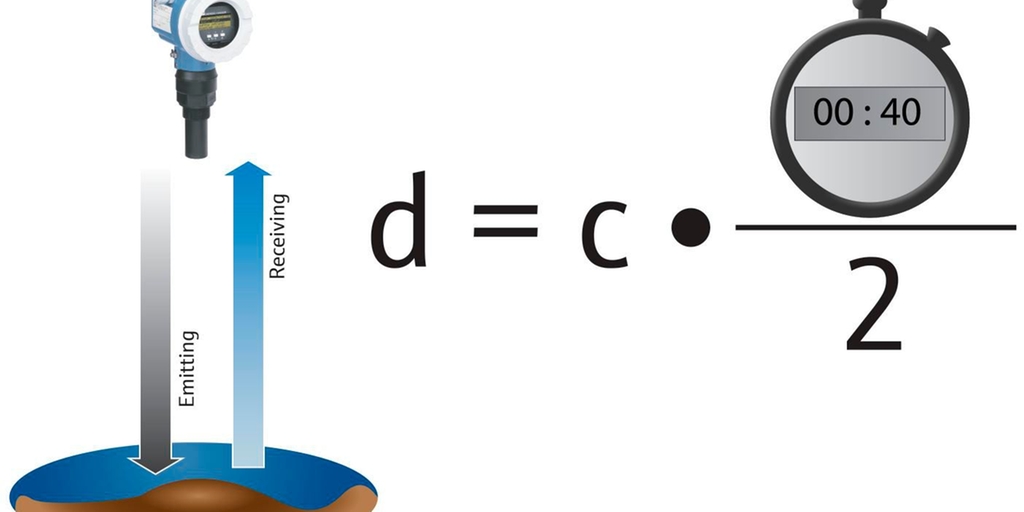

An ultrasonic level sensor sends a sound pulse that reflects from the surface of the liquid or solid in a vessel. The time of flight determines the level.

The most common technologies available for continuous level measurement are ultrasonic, free space radar, guided wave radar, capacitance, gamma and pressure. This paper will take a look at each technology and some typical applications.

When determining your level technology for your process what questions should you be asking yourself? What is the pressure and temperature of your process? Will there be foam or gas fumes associated with this process? Is there an agitator or turbulent surface in the process? What is the dielectric or specific gravity of your process?

A supplier to help you navigate continuous level

No matter what technology you choose to measure level, always look at the accuracy you want to achieve and the process conditions. In most applications, you will find there are multiple technologies that will work - with the final choice best determined by working with an experienced supplier of all of the leading level measurement technologies.