RTD temperature measurement

Technology, construction and benefits of resistance temperature detectors (RTD)

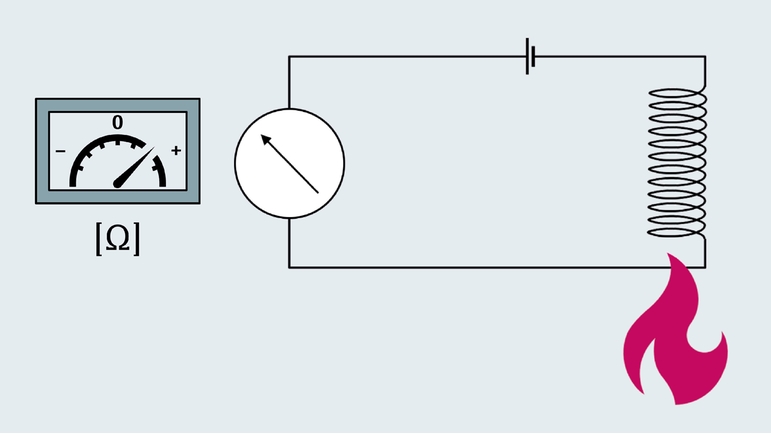

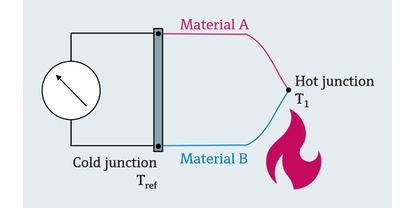

When measuring temperature, the choice of the sensor is one of the most important decisions to make. Thermocouples (TCs) and resistance temperature detectors (RTDs) are commonly used in industrial applications. Proven in the process industry for decades, RTDs work on the principle that the electrical resistance of the sensor metal increases as the temperature rises. This change in resistance is measured and converted into temperature readings.

Benefits

High accuracy over a wide temperature range

Nearly linear response, making them easy to calibrate and interpret

Suitable for a moderate temperature range: -200°C (300°F) to +850°C (1562°F)

Good long-term stability and repeatability

Low self-heating effect, resulting in minimal measurement errors

Temperature sensors with RTD technology

Our product finder helps you to search for suitable measuring devices, software or system components via product characteristics. Applicator leads you through an individual product selection via application parameters.

What are RTDs?

Resistance temperature detector types

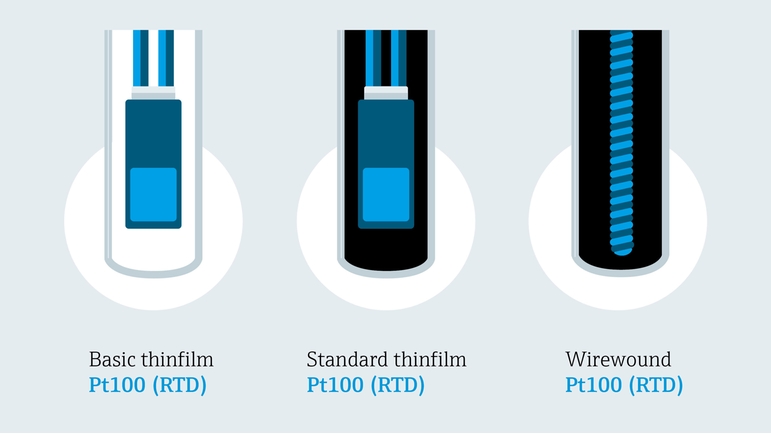

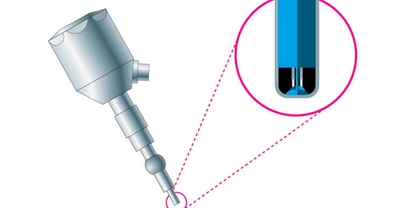

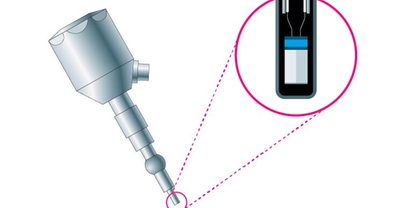

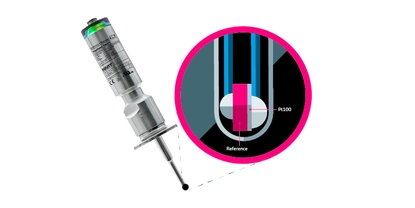

An RTD sensor is typically a length of wire made from a pure metal such as platinum, nickel, or copper. It is available either as a thin film sensor, where the wire is placed in a ceramic body, or as a wire wound in a helix construction around a glass or ceramic bobbin. The most commonly used RTDs are platinum Pt100 sensors (industry standard). The 100 in Pt100 represents the nominal resistance of 100 ohms at 0°C (32°F).

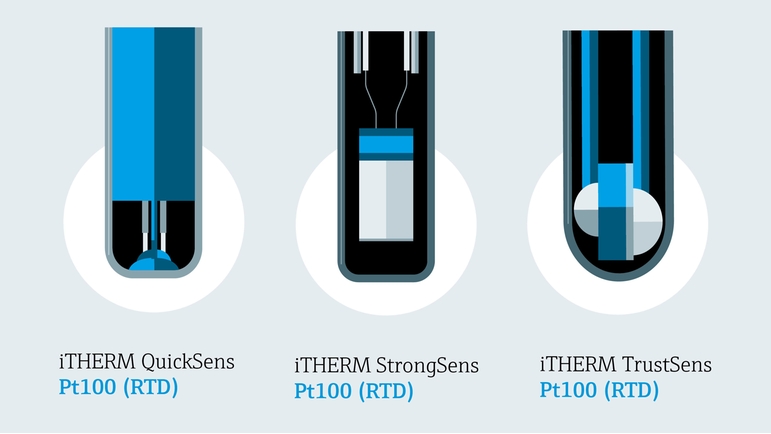

The Pt100 sensor is also known as a PTC, which stands for "positive temperature coefficient", meaning that the resistance increases as the temperature rises. A Pt100 RTD is suitable for the measurement of temperatures between -200°C (300°F) and +850°C (1562°F), depending on the sensor and the design. It is important to note that RTD sensors do not follow an ideal linear temperature-resistance curve and, unfortunately, the RTD becomes less linear as the temperature rises. The use of temperature transmitters can compensate these non-linearities. Endress+Hauser developed innovative, patented sensor technologies such as the iTHERM StrongSens with highest vibration resistance, the fast-responding sensor iTHERM QuickSens and the iTHERM TrustSens with self-calibration function. Endress+Hauser RTD instruments meet the IEC 60751 accuracy class A as standard.

The right sensor element for your application

Several factors influence the choice between TC and RTD thermometers, all of which depend on the specific application requirements.

Accuracy: RTDs are generally more accurate than TCs, especially in lower temperature ranges

Temperature range: TCs are suitable for higher temperature measurements, while RTDs are usually used for lower temperature measurements

Response time: TCs are normally faster responding than RTD thermometers

Durability: TCs can withstand harsher environments (pressure, vibration, corrosive environment etc.) than RTDs

Cost: In general, TCs are less expensive than RTD temperature sensors

Reliability: TCs are more susceptible to electromagnetic interference than RTDs

Material choice: Compared to RTD temperature sensors, TCs only offer a limited number of options for the specific temperature ranges

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |

Downloads

-

Temperature measurement for the process industry

Temperature Measurement - Thermometers and transmitters for the process industry

File size:

File name:

-

Endress+Hauser temperature sensor technologies

File size:

2 MB

File name:

Sensortechnologie_Thermometer_EN.pdf