Right from the start

Everything starts with the receipt of raw materials, support materials and additives. Process optimization in terms of efficiency can already begin during this step of the process.

For many food manufacturers, raw materials accounting is a highly important and frequently discussed topic. The idea is to measure the exact amount of delivered raw materials, such as milk, oil or alcohol, and then precisely allocate how much is used in each of the individual production steps. The goal is to provide as much transparency as possible and gain full cost control.

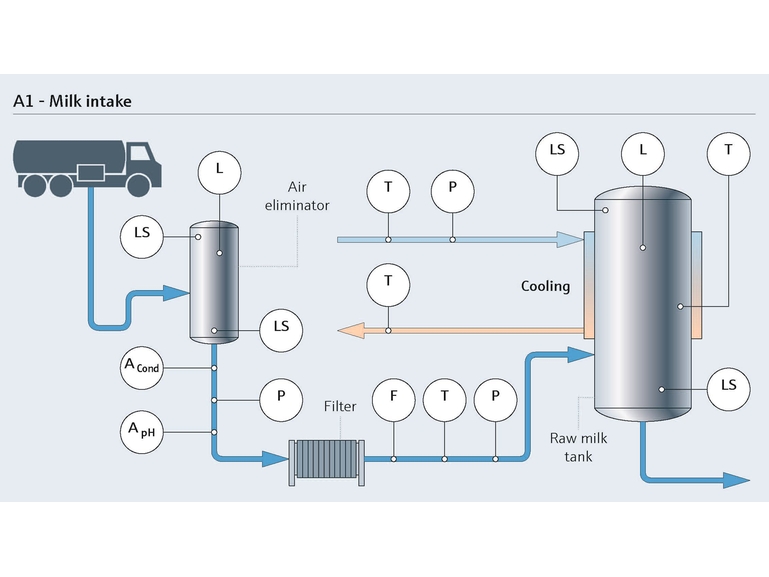

Process insights

Receiving and accounting raw materials is the first step in any food manufacturing process. This illustration shows the various measuring points during reception of milk.

Inline measurement

Measuring the reception of raw materials with a Coriolis flowmeter

Inline measurements with Coriolis-based Proline Promass Q flowmeters offer food manufacturers a one-of-a-kind opportunity to optimize their raw materials accounting. Thanks to the integrated, patented Multi-Frequency-Technology (MFT), measurement discrepancies caused by entrained air and gas in the liquid are virtually eliminated.

Gas entrainment is a frequently encountered problem in food manufacturing. Raw materials can easily mix with air in the tanks during delivery, distorting the measurement values at the delivery point and further down the process. With Promass Q, such problems are a thing of the past.

Overcome the challenges when receiving raw milk

Discover how Endress+Hauser solved the challenges with Meierei Barmstedt, a northern German dairy

Producers face huge challenges in food manufacturing. Unwanted entrained air or gas bubbles, for example, result in measurement errors of the raw material, such as when receiving raw milk. Proline Promass Q from Endress+Hauser solves this problem at Meierei Barmstedt, a northern German dairy, offering highly accurate measurement.

Related topics

Discover more opportunities where inline measurement can increase productivity