Accurate monitoring enables high availability and efficiency along the hydrogen value chain

Increase safety and achieve optimum quality in green hydrogen

Optimum quality of feedwater leads to increased availability and reduced LCOH (levelized cost of hydrogen). Monitoring H2S content in hydrogen from cavern storage helps to avoid corrosion issues downstream.

- Ensure highest purity of hydrogen as well as enhanced lifetime of the electrolyzer thanks to reduced risk of leaching metal ions into the feed water

- Non-invasive temperature sensors enable time-saving and user-friendly installation without process interruption

- Monitor the feedwater quality reliably while collecting data: increase process efficiency and availability thanks to enhanced process insights via Netilion, a cloud-based IIoT ecosystem

- Rely on accurate TDLAS technology to monitor hydrogen quality accurately: detect trace moisture and trace H2S in the ppm range

Accurate, stable measurement increases the plant availability

Enhance safety, availability and efficiency in your thermal power plant (TPP)

Our products enable reliable, accurate monitoring of fuel, water, steam and lime slurry, therefore enhancing availability, efficiency and safe operation while reducing cost.

- Monitoring pH and gypsum concentration is key to reduce consumption of lime slurry and achieve optimum DeSOx, therefore reducing SOx emissions

- Continuous liquid analysis offers instant problem alerts, data can be transferred and accessed anytime, anywhere via state-of-the-art web technologies

- Clamp-on devices enable user-friendly installation without process interruption for reduced downtime

Smart Support

Direct access to Endress+Hauser expertise through our online knowledge base and remote support sessions with technical engineers who ensure availability and prompt response times.

- Maximize process availability and meet production objectives

- Enhance plant and operator safety with minimized exposure to hazardous conditions

- Reduce unnecessary travel-related emissions to contribute to your sustainability and net zero targets

Dynamic Installed Base Analysis

Use expert recommendations with frequent insights to improve the lifecycle management of your measuring instruments and ensure compliance with safety requirements.

- Increase your process availability through professional advisory guidance

- Identify inefficiencies and prevent breakdowns with continuous evaluation of the installed base maintainability

- Improve sustainability of your operations by adopting a suitable maintenance and migration strategy

- Gain full transparency and increase accessibility of your installed base information

Find the product that best fit your application

Are you unsure which instrument to select for your specific application and measurement point? Our Applicator tool makes product selection for your industry easy. Try it out!

Precise measurements along the hydropower plant ensure efficiency and uptime

Increase safety and efficiency in your hydroelectric power plant (HPP)

The level of the reservoir and the afterbay as well as the flow rate in the penstock are important measurements for monitoring the efficiency of your power plant. Changes in efficiency can indicate a problem with a turbine. Monitoring the oil and air cooling systems reliably helps to increase the overall availability of the plant.

- Safely monitor cooling efficiency with robust transmitters to minimize downtime

- Ensure stable water flow and oil quality (viscosity and/or density) with short or no inlet runs saving space and costs while increasing plant lifetime and durability

- Measure the level of reservoir, pump sump and afterbay to monitor efficiency with non-invasive, reliable radar sensors

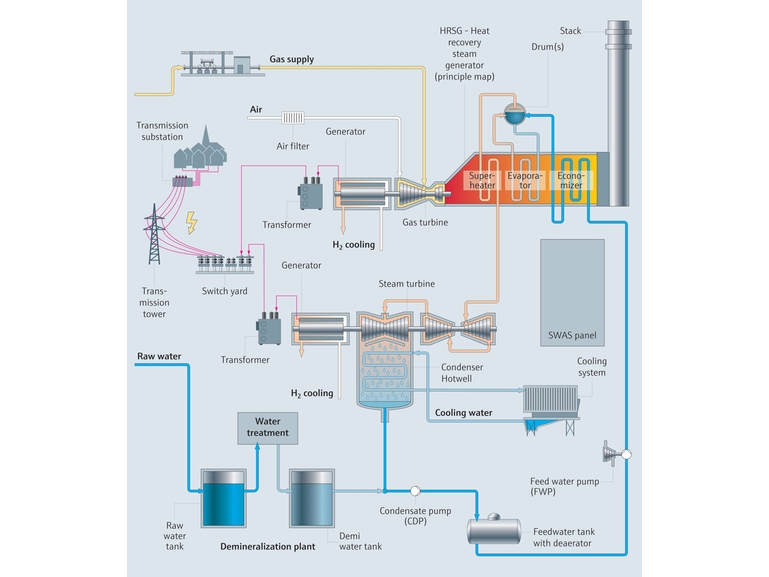

Combined Cycle Power Plant

Increased safety and efficiency in your CCPP

- Increase safety monitoring concentrations of disinfectants and TOC: Low concentrations or lack of disinfectant in the cooling water system may lead to the formation of harmful bacteria that increase risk to personnel and potential for downtime. Even the lowest concentrations of Total Organic Carbon (TOC) in make-up water may lead to plant shutdowns.

- Improve process availability with Dynamic Installed Base Analysis: Gain transparency about your assets, continuously manage the maintenance requirements for your measuring devices and streamline the ordering of MRO devices.

- Increase efficiency monitoring cooling water and fuel flow reliably: Flow technologies often require inlet and outlet runs. Using Promass Q for measuring natural gas flow overcomes this issue at an excellent uncertainty of 0.25%. For cooling water, Promag W 0 x DN FB does the same even without pressure drop and comes with integrated monitoring of conductivity.

Deeper insights into process and instrumentation performance

Smart sensors collect real-time data from processes and monitor equipment and health, keeping you informed about product and asset performance. Digitizing production processes provides data visualization opportunities for personnel working with the process who typically do not have access to the data, creating data transparency. Endress+Hauser's Netilion can do just that, empowering end users to make the best decisions.

%20with%20flange%20connections%20for%20process%20applications%20-%20PP01.jpg)