Pump monitoring with EdP transmitters

An electronic differential pressure transmitter can improve efficiency of pump systems

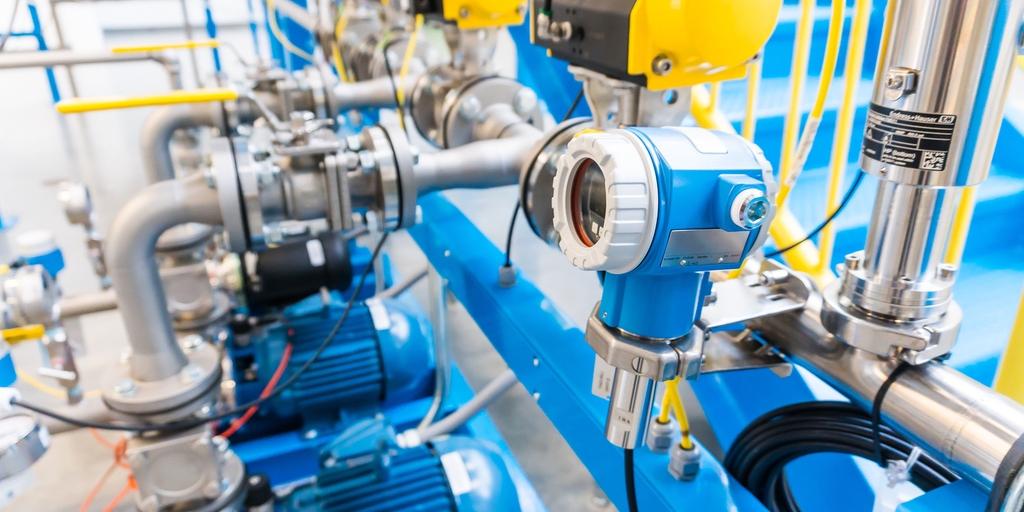

Endress+Hauser FMD71 EdP differential pressure transmitter mounted across a pump.

Companies incur thousands, if not millions of dollars in maintenance costs to keep their pumping systems in good health. Predictive maintenance is one of the best ways to cut pump operating costs. One effective predictive maintenance technique uses an electronic differential pressure transmitter to not only monitor instantaneous pump performance, but also to identify issues related to pump health and efficiency.

Monitoring differential pressure

All pumps perform best when they are at, or very close to, their Best Efficiency Point (BEP) on their pump curve. The BEP is defined by the manufacturer on its pump curve, and is typically 70-85% of the shut-off head or maximum differential pressure between the suction and discharge. Helping the pump operate at the BEP is the single most important aspect for prolonging pump life, and cutting maintenance time and costs. Download the white paper to learn the potential ROI!