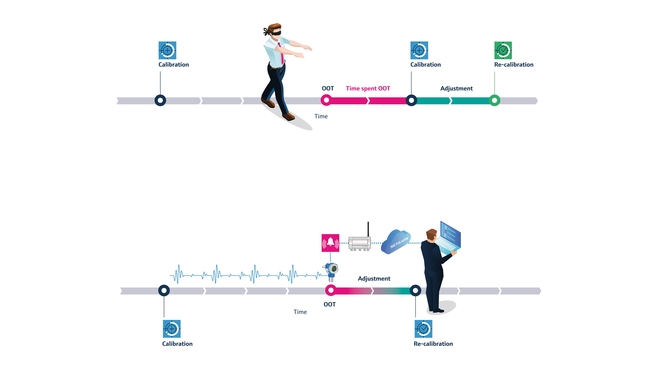

Calibration program intervals depend on process criticality and the long-term stability of measurement instrumentation. When it's time for calibration, process interruption is inevitable and seals must be broken to apply a calibration fluid to the instrument. The latest generation of mass flowmeters are so reliable that calibration cycles of two years or longer are possible. However, with extended intervals comes an increased risk of a random failure going undetected in the meantime.

Key facts

20%

only 20% of instruments are set up with an ideal calibration interval

Optimize your calibration and cGMP compliance

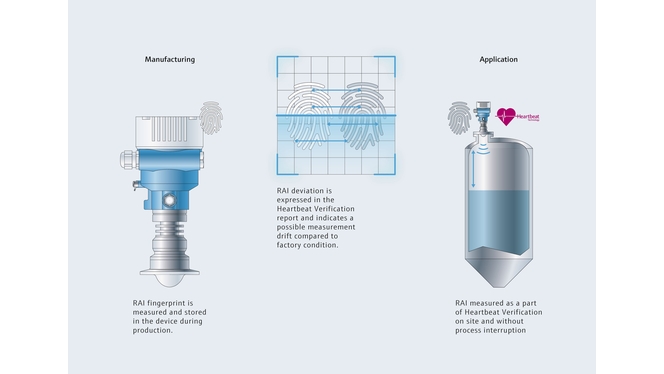

Heartbeat Technology with Radar Accuracy Index (RAI): Level measurement accuracy verification with the new generation Micropilot 80 GHz radar sensor.

Heartbeat Technology Radar Accuracy Index (RAI) is a patented technology that assesses the reference accuracy of a Micropilot without process interruption.

Increased reliability increases calibration intervals but also risk of an undetected Out of Tolerance (OOT) event.

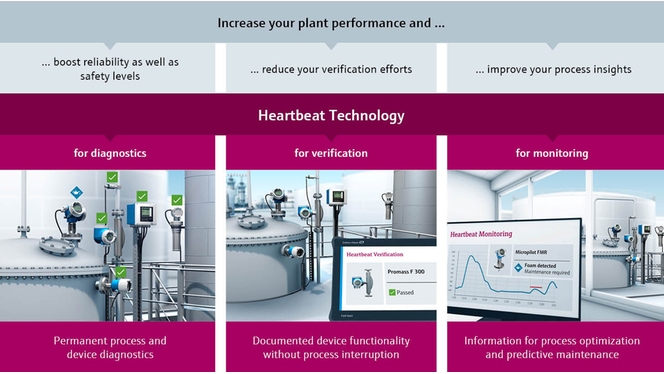

Increase your plant performance with Heartbeat Technology for diagnostics, verification and monitoring

Heartbeat Technology with Radar Accuracy Index (RAI): Level measurement accuracy verification with the new generation Micropilot 80 GHz radar sensor.

Heartbeat Technology Radar Accuracy Index (RAI) is a patented technology that assesses the reference accuracy of a Micropilot without process interruption.

Increased reliability increases calibration intervals but also risk of an undetected Out of Tolerance (OOT) event.

Increase your plant performance with Heartbeat Technology for diagnostics, verification and monitoring

Combining wet calibration with Heartbeat Verification

Tested and independently certified by TÜV, Heartbeat Verification fulfils all requirements specified by DIN EN ISO3 and can be used interchangeably with traditional wet calibration for traceable instrument checks. Reliability is increased, and uncertainties between calibrations are significantly reduced. In contrast to wet calibration, Heartbeat Verification does not use a primary fluid but relies on redundant internal references to verify the device functionality.

Our expertise in the field

A baseline of values is established during the original factory calibration and permanently stored both in the non-volatile, secure memory of the flowmeter, and on file at the factory. When Heartbeat Verification is performed on site the test data is compared with this baseline to detect any electronic component drift or mechanical deterioration of the instrument. Critical electronic circuits are implemented redundantly allowing the detection of hardware failures.

- In comparison to wet calibration, integrated verification functions in measuring devices such as Promass 100/300/500 Coriolis flowmeters lead to a time saving of at least 80% and extended calibration cycles.

- Still wondering how exactly Heartbeat Technology can pass regulatory audits? Read our white paper "Heartbeat Technology authority recognition" on how in-situ verification technologies can be used even in GMP environments.

Extend calibration cycles with Heartbeat Technology

Instruments with Heartbeat Technology deliver consistent and reliable measuring values for years and years of operation. Calibration frequency can in many cases be significantly reduced without jeopardizing regulatory compliance. Fewer wet calibrations reduce the expenses for the calibration program which lead to a better overall equipment effectiveness (OEE) as it increases plant availability.

Our expertise in the field

Less downtime for instrument calibration and fewer unexpected shutdowns will improve operations efficiency and operational excellence. Reliable data, and certified proof that the measured process value is correct, reduce the risk for product quality issues and therefore supports the goal of reaching highest possible patient safety.

- Micropilot FMR63B can extend calibration cycles by means of Heartbeat Technology with Radar Accuracy Index, which allows the radar accuracy of the device to be verifies without process interruption.

- The iTHERM TM371 represents the world’s first RTD sensor capable of fully automated in-situ self-calibration. The patented innovation has been extensively tested and verified in lab and field trials. Read more in our white paper.

- Want to read more on how technologies such as Heartbeat Technology can reduce or even eliminate wet calibrations? Read our white paper "Quality by Design in Process Instrumentation".

Verification made simple and fast

Heartbeat Verification is simple. The instrument does not need to be taken out of service, nor the process stopped. The instrument will continue to deliver measuring results throughout. Taking around 30 seconds Heartbeat Verification is also fast. It can be started remotely from the safety of the control room, and flexibly, for example on a daily basis or before a batch. A full Heartbeat Verification report is generated internally in the device every time a device verification is performed.

Our expertise in the field

This report comes in a tamper-proof PDF format and is easily accessible directly from within the instrument. It can be downloaded through any asset management system or via the integrated web server. Using Heartbeat Verification during the lifecycle provides traceable and audit-safe test documentation ready for inspection.

Benefits

Instruments with Heartbeat Technology are designed to deliver consistent and reliable measuring values for many years of operation. The Heartbeat Verification capabilities allow for wet calibrations to be significantly reduced without jeopardizing compliance. Fewer calibrations also lead to better overall equipment effectiveness and increases plant availability. The reliable data and certified proof that process values are correct between calibration events reduces the risk of quality issues.

Key facts

1.5 hours

time saved per verification

Key facts

500 - 1'000 Euro

saved annually on calibration depending on the device

How we can help

Inbuilt verification technology such as Heartbeat Technology by Endress+Hauser provides security between each calibration program and can even be used in strictly regulated industries according to certification by TÜV. The increased availability and measuring point reliability that Heartbeat Technology offers are just two of the many benefits driving life sciences industry users to optimize their calibration procedures. Combining wet calibrations with Heartbeat Verification helps you to:

- Decrease calibration frequency and increase intervals between wet calibrations

- Increase confidence in your measurements between wet calibrations

- Fulfil the traceability requirements according to ISO 9001 - third-party certified

- Ensure measurement accuracy without process interruption