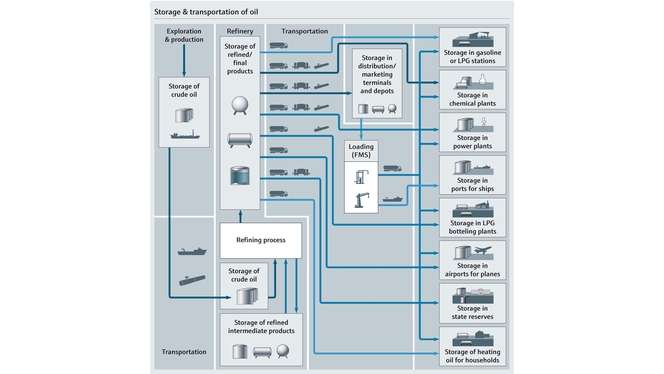

Storage and distribution in oil and gas industry operations poses competing pressures. Intense market rivalry places an emphasis on plant efficiency as never before. Tank capacity must be optimized, inventory strictly controlled, and processes optimized for loading and transfer. With such imperatives come increased risks to operators and the environment, therefore ensuring operational safety is also vital. The Endress+Hauser portfolio enables simple, safe operations with optimal performance.

Key facts

75%

of the world tanker fleet are being independently owned. In addition, in the natural gas transport and storage network, nearly all is transported through interstate pipelines owned by at least 70 to 80 companies to over several hundred underground storage facilities. As a result, the storage and transportation represent a labyrinth needing rigorous inspections, compliance standards, and regulations.

Improve the safety of your storage and distribution areas

Storage and distribution

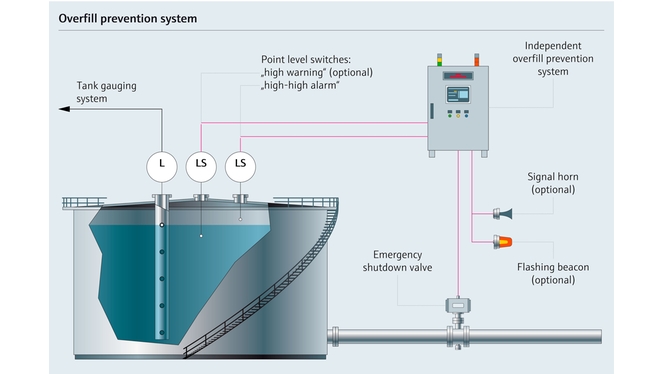

Safely monitor your tank and prevent hazardous overflow with an intelligent system that is able to operate by itself.

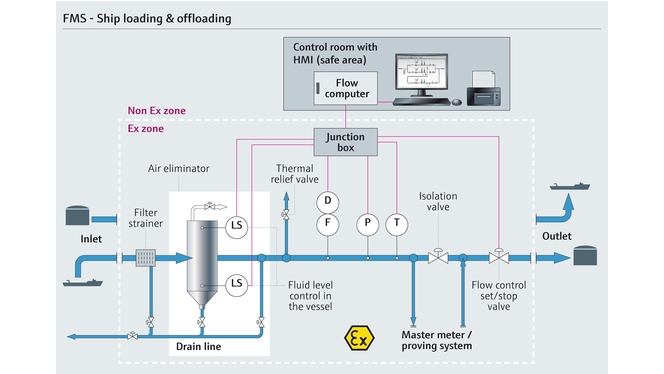

Make your transaction more efficient, more reliable and safer with ship loading custody metering systems.

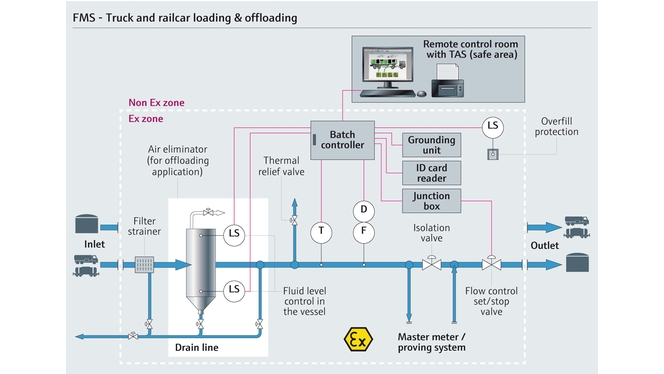

Safe truck or railcar loading and offloading application with custody metering systems.

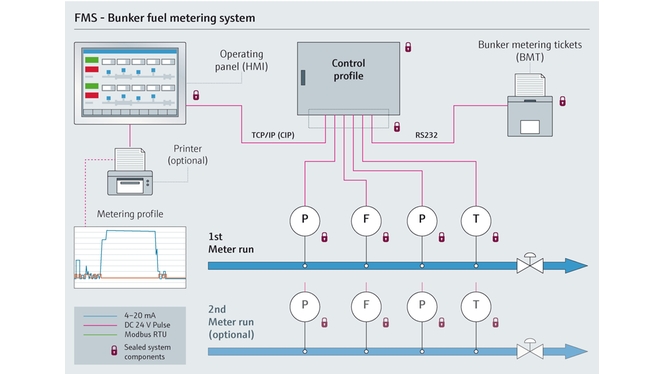

Accurate bunker fueling: direct mass measurement without converting volume, and higher security with sealed individual devices and entire measuring system to protect from unintentional tampering.

Storage and distribution

Safely monitor your tank and prevent hazardous overflow with an intelligent system that is able to operate by itself.

Make your transaction more efficient, more reliable and safer with ship loading custody metering systems.

Safe truck or railcar loading and offloading application with custody metering systems.

Accurate bunker fueling: direct mass measurement without converting volume, and higher security with sealed individual devices and entire measuring system to protect from unintentional tampering.

Accurate, safe custody metering

Loading and offloading processes can give rise to disputes regarding both quantity and quality. Such situations can be avoided with the higher levels of precision and transparency offered by certified custody transfer metering solutions.

Our expertise in the field

Both highly accurate and reliable, Endress+Hauser Coriolis flowmeters can measure multiple parameters with minimal maintenance and recalibration. Transfer capacity can be increased with guaranteed transparency, accuracy and safety in the process.

- Increase handling volume with larger meter sizes

- Load more safely thanks to a higher tolerance of air/gas content than with mechanical meters

- Spur plant performance and efficiency

- Achieve operational excellence from start-up into the long term with our commissioning services

Reliable bunker fuel metering

Error-prone volume to mass calculations and air pockets in the fuel can make measurement of bunker fueling an expensive and uncertain process.

Our expertise in the field

Replacing traditional quantity measurement practices with bunker fuel metering systems such as the Endress+Hauser Coriolis flowmeter can increase transparency. Multiple process parameters can be simultaneously monitored via a control panel during fueling. Moreover, air pockets are corrected in the measurement during tank emptying.

- Increase profitability

- Improve measuring results

- Ensure trust between buyers and suppliers

Optimized storage tank overfill prevention

When handling combustible or petrochemical products, tank overfills can increase risk and danger considerably. Overfill prevention systems play a vital role in mitigating such risks.

Our expertise in the field

Endress+Hauser has partnered with Rockwell Automation to develop a pre-configured solution package with independent safety certification for the entire instrumentation safety loop, from measurement and control to element correction. The solution complies with industry best practices and standards API 2350 and IEC 61511.

- Increase reliability and reduce operational risk

- Optimize engineering and commissioning time

- Streamline maintenance expenses using Heartbeat verification and instrument verification and/or proof testing services

Versatile, effective terminal management

Market evolution, intense competition, regulatory and social environment changes, all are contributing to an increasing need for terminal automation.

Our expertise in the field

From road, rail, barge and ship loading bays to depots and terminals, Endress+Hauser offers automation systems for sites of any scale and for all applications, including management of process sub-systems and connections to business systems.

- Reduce installation, operation and maintenance costs

- Leverage custody transfer metering skids conformant with API and MID

- Enhance accuracy for better volume and mass

Benefits

We continuously optimize our processes and use of innovative technologies which enable us to extend the frontiers of measurement, control and automation engineering. Customers find safe and efficient solutions for their benefit.

Key facts

<5 min

is the time needed to run a proof-testing on 16 tanks

Key facts

17+

years of functional safety standards IEC 61508 (quality, safety and reliability) applied

Key facts

24/7

is the visibility you get with our inventory monitoring solutions

How we can help

From precise and efficient silo and tank gauging to highly accurate custody transfer and terminal automation, Endress+Hauser offers a complete range of technologies and installations, which combined with scalable software packages offer uniform operating and safety concepts for high performance and yet simple and safe operations.

- Compliance with internationally recognized standards and recommendations such as: API, OIML, SIL, IP, NORDSOK, NACE

- Product lines certified according to hazardous area standards such as: ATEX, FM, TIIS Safety by Design

- State of the art technologies (IEC 61508 SIL 2 and up to SIL 3 for homogeneous-redundant application)