Nitrate sensor improves efficiency and cost-effectiveness

Water Remediation Technology increases gallons per cycle and reduces the cost of salt consumption and waste brine disposal

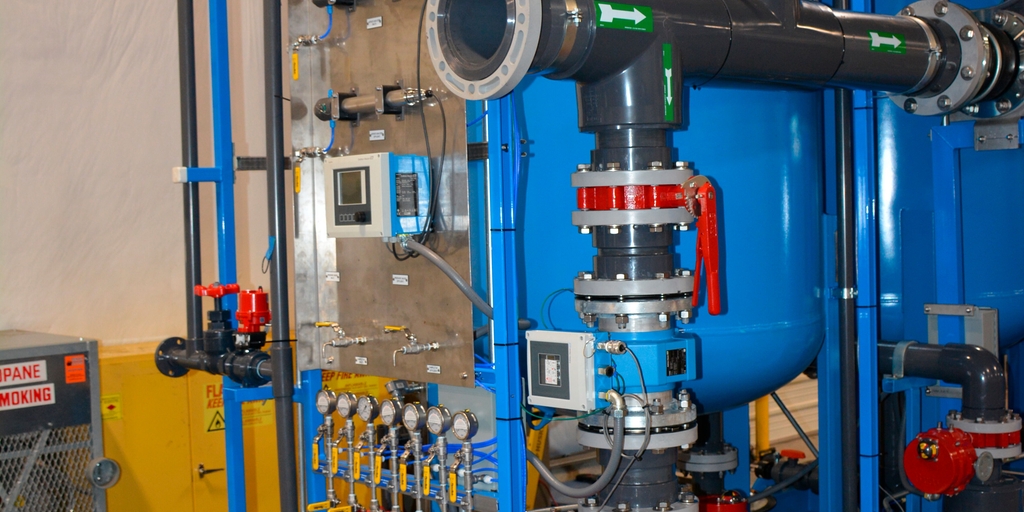

Colorado-based Water Remediation Technology (WRT) LLC specializes in providing processes to remove radium, uranium and other contaminants from water. WRT recently used Endress+Hauser equipment to make major improvements to its nitrate removal system. By working with Endress+Hauser and one of its representative partners, WRT reduced operating costs and eliminated the risk of nitrate dumping which occurs when the media is run past the point of exhaustion.

.jpg)

Online Nitrate sensor maximizes efficency

-

If WRT had not implemented online nitrate sensors, they would have advised running the cycle length—at most—to 90% of the theoretical maximum capacity, i.e., 207,000 gallons per cycle.

Stringent requirements create a need for change

WRT has a customer with stringent requirements on their waste volumes and the amount of chloride they can send to waste from their nitrate removal system. For this customer, WRT needed to get waste volumes down to significantly lower numbers than a typical nitrate removal system could provide. To accomplish this, WRT needed to extend their customer’s run times to fully utilize the media capacity between each regeneration.

Endress+Hauser offers a valuable solution

Using the Viomax CAS51D digital nitrate sensor and the Liquiline CM444 four-channel transmitter, WRT was able to eliminate waste. The Viomax CAS51D is cost-effective, easy to use, requires no consumables and is safe and environmentally friendly.

Furthermore, the Liquiline CM444 is a state-of-the-art transmitter that allows users to connect up to four Endress+Hauser Memosens sensors of their choice from over 12 measurement parameters and has the ability to expand to eight total sensors.